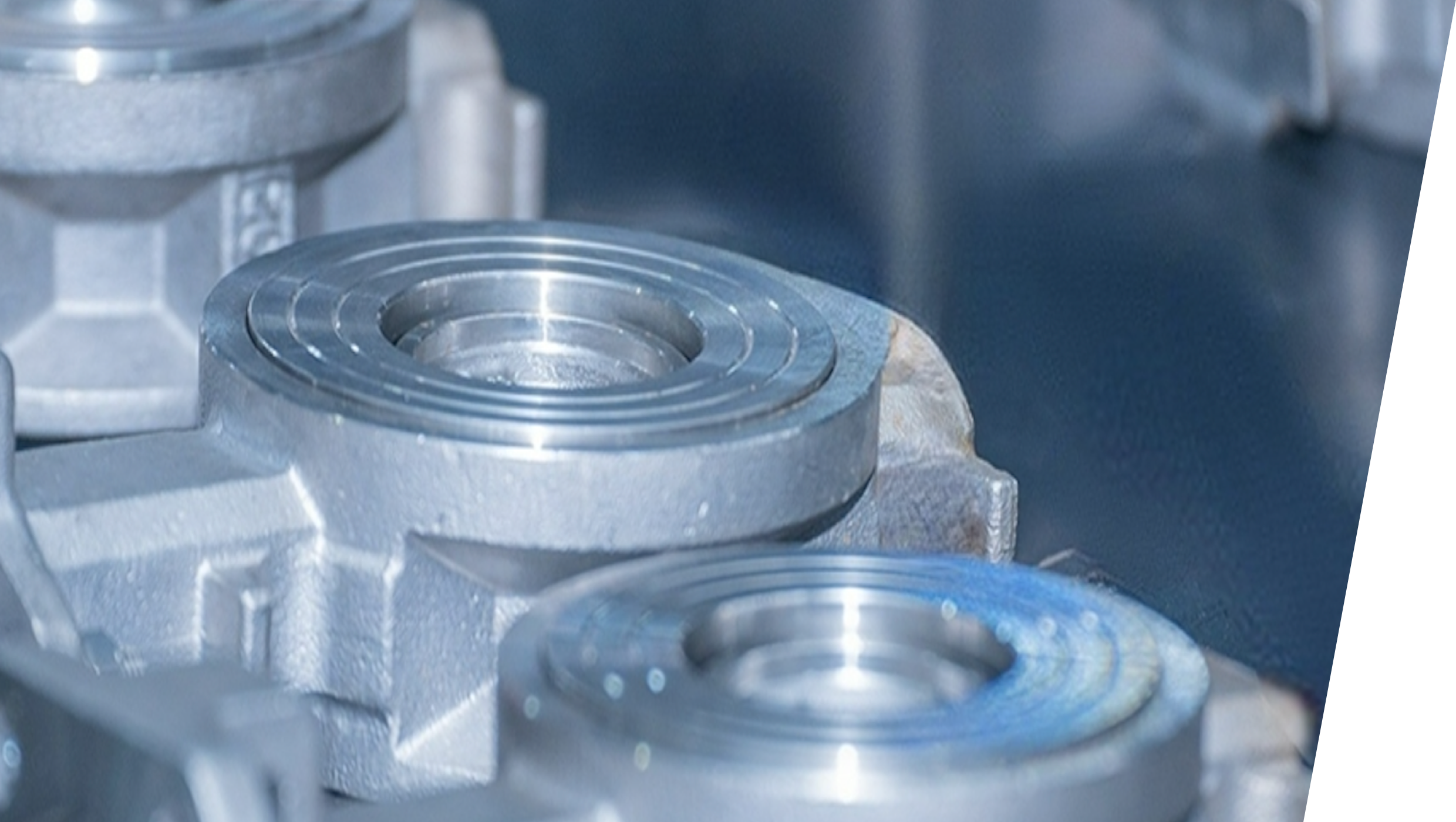

Flange Eccentric Butterfly Valve

Parameters

- Product specifications DN50-DN1200

- valve body QT450-10, WCB, stainless steel, etc.

- valve plate ductile iron nylon, 304SS, etc.

- valve shaft 45 #, 416SS, etc.

- valve seat EPDM, NBR, PTFE, etc.

- drive electric, pneumatic, turbo, handle

- medium temperature -15 ℃ -120 ℃.

Applicable industries

Water, water vapor, oil, air, flue gas, gas, etc.

high-temperature water and steam systems, frequent changes in operating temperature area heating

vacuum systems

shipbuilding and heavy industry

petrochemical, chemical, electric power, metallurgy and other industries

Product overview

Double eccentric butterfly valve, also called high performance butterfly valve, is further improved on the basis of single eccentric butterfly valve, its structural characteristics of the butterfly plate rotary axis (i.e., stem axis) and butterfly plate sealing cross-section offset by one size, and with the valve body channel axis offset by one size. Compared with the centerline butterfly valve, the effect of double eccentricity makes the valve open and the butterfly plate can be quickly separated from the valve seat, greatly eliminating the unnecessary excessive squeezing and scraping phenomenon between the butterfly plate and the valve seat, reducing the opening torque, lowering the wear and tear, and improving the life of the valve seat.

- Product parameters

- Technical features

- Dimensions

- Installation guide

- Application examples

-

Nominal pressure PN10~16 Strength test pressure Nominal pressure*1.5MPa Seal test pressure Nominal pressure*1.1MPa Applicable temperature -10℃-80℃ Driving mode Electric, pneumatic, turbine, handle -

1. Simple and compact structure, light weight, 90°rotation, flexible and rapid opening and closing.

2. Eccentric structure is adopted to reduce the friction of sealing ring and prolong the service life of the valve.

3. The sealing structure is reasonably designed to achieve safe sealing, zero leakage, and can adapt to the more severe working conditions.

4. Replacement of valve plate sealing ring, O-ring, valve plate, spindle and other materials, can be applied to a variety of media and different temperatures.

5. The valve body has a foot support, which can realize the vertical or horizontal installation of the valve.

6. Easy to install and dismantle, easy to maintain. -

DN L1 PN10-φD1 PN10-n-φh PN16-φD1 PN16-n-φh DN50 108 125 4-18 125 4-18 DN65 112 145 8-18 145 8-18 DN80 114 160 8-18 160 8-18 DN100 127 180 8-18 180 8-18 DN125 140 210 8-18 210 8-18 DN150 140 240 8-22 240 8-22 DN200 152 295 8-22 295 12-22 DN250 165 350 12-22 355 12-26 DN300 178 400 12-22 410 12-26 DN350 190 460 16-22 470 16-26 DN400 216 515 16-26 525 16-30 DN450 222 565 20-26 585 20-30 DN500 229 620 20-26 650 20-33 DN600 267 725 20-30 770 20-36 DN700 292 840 24-30 840 24-36 DN800 318 950 24-33 950 24-39 DN900 330 1050 28-33 1050 28-39 DN1000 410 1160 28-36 1170 28-42