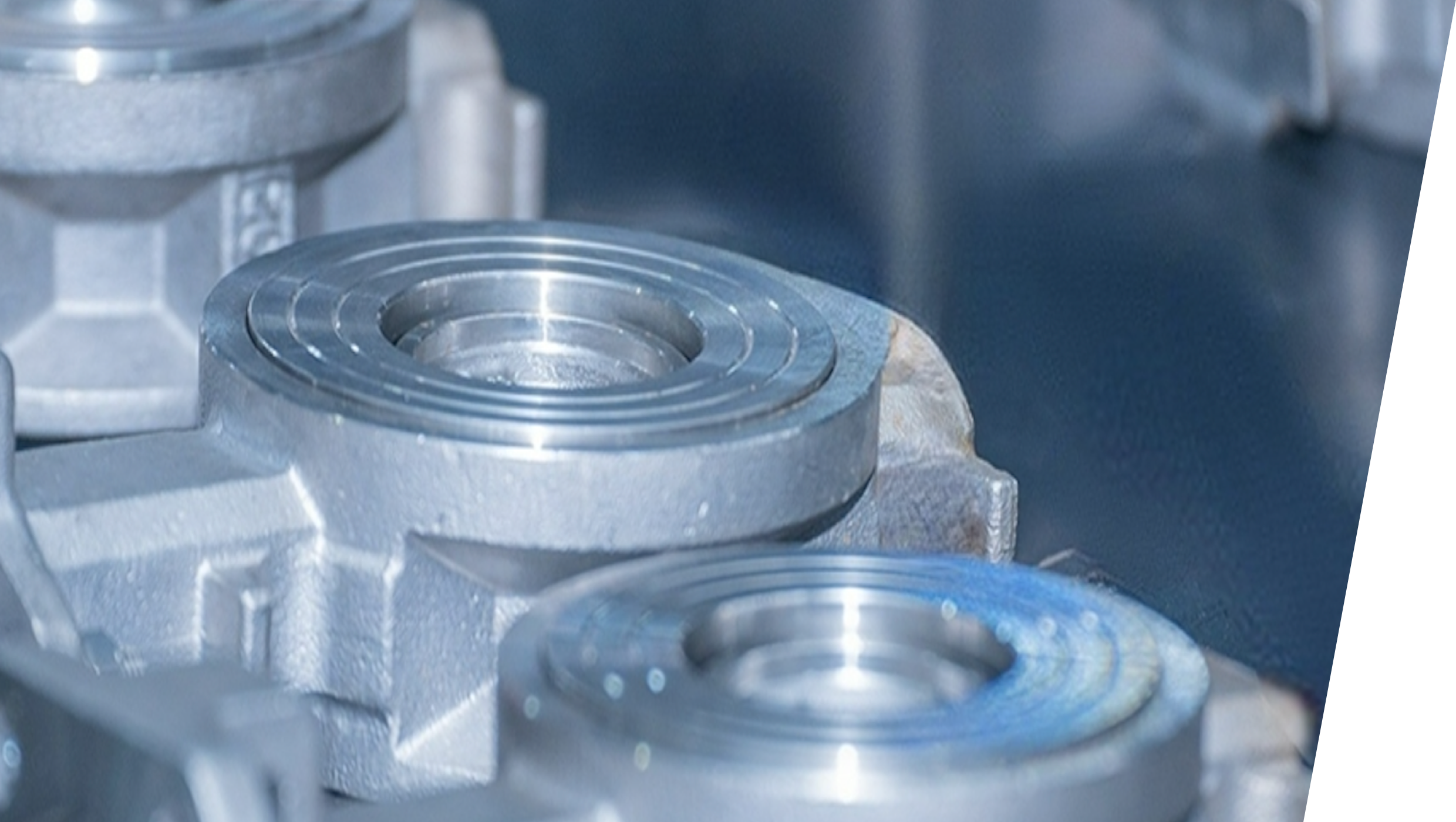

Wafer-Style Centerline Butterfly Valve

Parameters

- Product specifications DN50-DN1200

- valve body QT450-10, WCB, stainless steel, etc.

- valve plate ductile iron nylon, 304SS, etc.

- valve spindle 45 #, 416SS, etc.

- valve seat EPDM, NBR, PTFE, etc.

- drive electric, pneumatic, turbo, handle

- medium temperature -15 ℃ -120 ℃.

Applicable industries

Domestic water supply and drainage, fire water system

central air-conditioning system, sewage treatment system

water, gas, oil, chemical industry

construction, water treatment, etc.

.

Product overview

Simple structure, excellent universal interchangeability, and low cost. The valve stem seal is resistant to deformation, effectively preventing leakage, with overall superior support performance, ensuring stability and durability. Minimal use of rubber in the valve seat reduces potential expansion effects, making it easier to control torque within an appropriate range. The valve seat sealing surface and backing are integrated, minimizing deformation and offering high strength.

- Product parameters

- Technical features

- Dimensions

- Installation guide

- Application examples

-

Nominal pressure PN10~64 Strength test pressure Nominal pressure*1.5MPa Seal test pressure Nominal pressure*1.1MPa -

1. Simple structure, good general interchangeability, low price.

2. The valve stem seal is not easy to deform so as to avoid the valve stem leakage phenomenon, the overall support performance is good, stable and firm.

3. The amount of seat rubber is small, the potential impact of expansion is small, easy to control the torque in the appropriate range.

4. The sealing surface of the valve seat and the backrest are integrated, which reduces the deformation of the valve seat and has high strength. -

DN L1 PN10 PN16 φD1 n-φh φD1 n-φh DN50 42.6 125 4-18 125 4-18 DN65 45.6 145 8-18 145 8-18 DN80 45.6 160 8-18 160 8-18 DN100 51.6 180 8-18 180 8-18 DN125 55.6 210 8-18 210 8-18 DN150 55.6 240 8-22 240 8-22 DN200 59.6 295 8-22 295 12-22 DN250 67.6 350 12-22 355 12-26 DN300 77.6 400 12-22 410 12-26 DN350 77.6 460 16-22 470 16-26 DN400 102 515 16-26 525 16-30 DN450 114 565 20-26 585 20-30 DN500 127 620 20-26 650 20-33 DN600 154 725 20-30 770 20-36 DN700 163 840 24-30 840 24-36 DN800 188 950 24-33 950 24-39 DN900 203 1050 28-33 1050 28-39 DN1000 216 1160 28-36 1170 28-42 DN1200 276 1380 32-39 1390 32-48 -