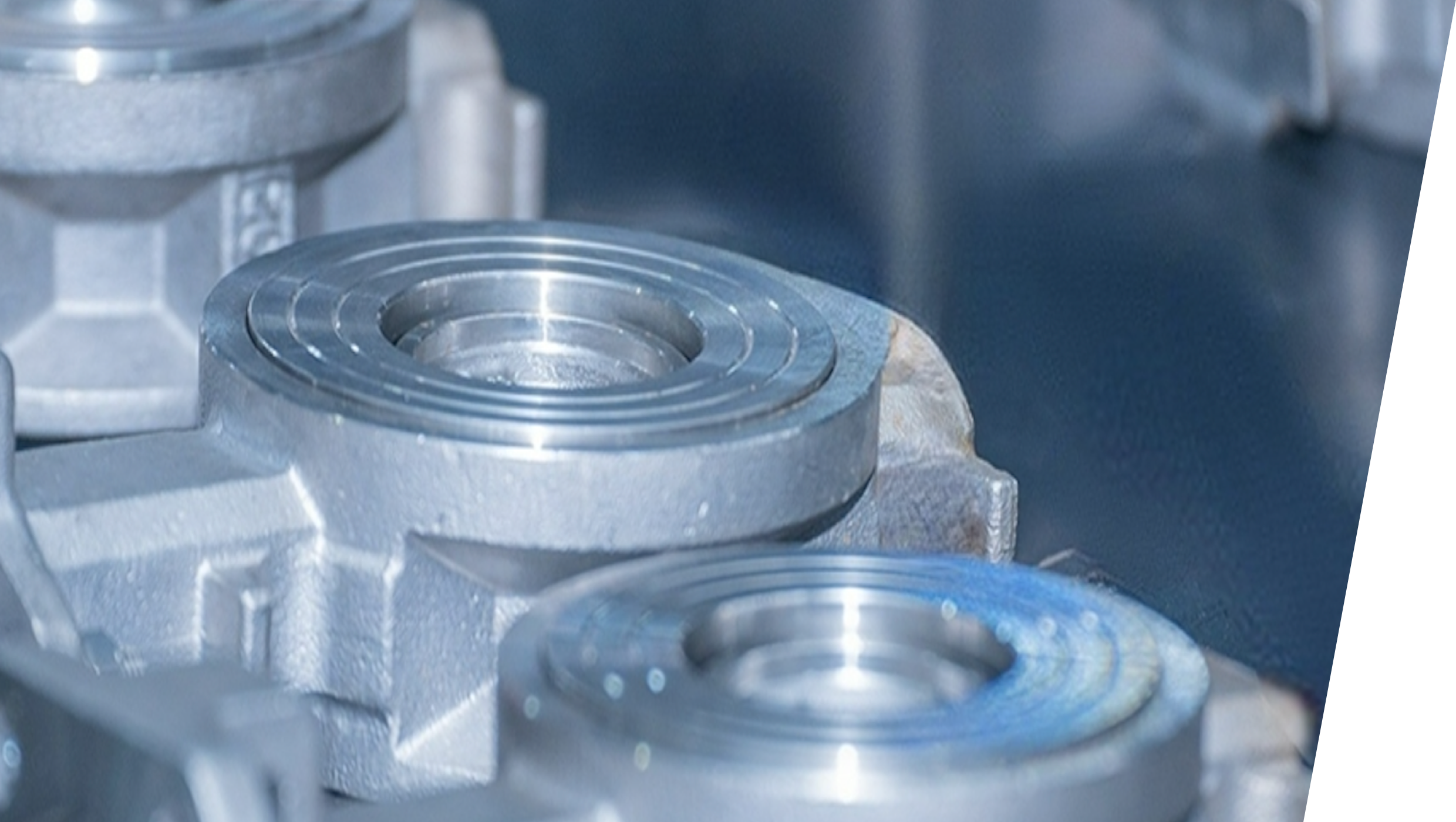

Single Wafer Centerline Butterfly Valve

Parameters

- Product specifications DN50-DN1200

- valve body QT450-10, WCB, stainless steel, etc.

- valve plate ductile iron nylon, 304SS, etc.

- valve spindle 45 #, 416SS, etc.

- valve seat EPDM, NBR, PTFE, etc.

- drive electric, pneumatic, turbo, handle

- medium temperature -15 ℃ -120 ℃.

Applicable industries

Domestic water supply and drainage, fire water system

central air-conditioning system, sewage treatment system

water, gas, oil, chemical industry

construction, water treatment, etc.

.

Product overview

Butterfly valve is a kind of valve that uses disc type opening and closing parts to reciprocate about 90° to open, close or regulate the flow of medium. It not only has the advantages of simple structure, small size, light weight, material consumption, small installation size, small driving torque, easy to operate, rapid, and can also have a good flow control function and close the sealing characteristics, is one of the fastest-growing valve varieties in recent years. Butterfly valve is easy to combine with various driving devices, has good durability and reliability. Its use in a wide range of fields, the use of varieties and the number of rising trend, and to high temperature, high pressure, large diameter, high sealing, long life, excellent regulating characteristics, as well as a multi-functional development of the valve, its reliability and other performance indicators have reached a high level.

- Product parameters

- Technical features

- Dimensions

- Installation guide

- Application examples

-

公称压力Nominal pressure PN10~64 强度试验压力Strength test pressure Nominal pressure*1.5MPa 密封试验压力Seal test pressure Nominal pressure*1.1MPa -

1、The valve body is LT type, which can be used at the end of pipeline.

2、The sealing ring of ‘○’ type is directly set in the shaft hole of the valve body, which has better sealing and eliminates the occurrence of internal leakage.

3、Narrow band sealing ring and spherical butterfly plate organic combination, so that the butterfly plate before closing torque will not increase.

4、The convex circle on the top of the valve seat can avoid the possibility of the valve being installed incorrectly and the torque of the valve being sharply increased by the serious deformation of the valve seat. -

DN L1 PN10 PN16 φD1 n-φh φD1 n-φh DN50 42.6 125 4-M16 125 4-M16 DN65 45.6 145 8-M16 145 8-M16 DN80 45.6 160 8-M16 160 8-M16 DN100 51.6 180 8-M16 180 8-M16 DN125 55.6 210 8-M16 210 8-M16 DN150 55.6 240 8-M20 240 8-M20 DN200 59.6 295 8-M20 295 12-M20 DN250 67.6 350 12-M20 355 12-M24 DN300 77.6 400 12-M20 410 12-M24 DN350 77.6 460 16-M20 470 16-M24 DN400 102 515 16-M24 525 16-M27 DN450 114 565 20-M24 585 20-M27 DN500 127 620 20-M24 650 20-M30 DN600 154 725 20-M27 770 20-M33 -